The Ultimate Guide to Cannabis Equipment Maintenance

In the world of cannabis cultivation, your equipment is your best friend. Keeping it in pristine condition isn't just about prolonging its lifespan;...

Whether they are packed by hand or machine, a pre-roll cone smokes better when it's packed evenly and finished symmetrically. Experienced consumers know that cones should be evenly and densely packed, filled with a coarse grind for proper air flow, and twisted at the top for a balanced light. At the industrial level, automated pre-roll machines must be as gentle as the human hand and even more accurate.

When an individual packs their own cone, they are subject to their own human error. But when a consumer buys a pre-roll at a dispensary, they expect it to burn evenly, smoke smoothly, and taste just like the strain they purchased.

To keep up with growing demand, manufacturers need fast, accurate, and high-capacity pre-roll machines. While the joint is a simple concept, each element of the pre-roll must be meticulously handled and prepared for sale. Everything from the environment in which the pre-rolls are packaged to the precision with which the pre-roll is finished affects the quality of the final product. With the right equipment, manufacturers can produce pre-rolls that set industry standards and build lasting customer loyalty.

Many of the medicines developed in the last century were derived from naturally occurring molecules, and the maintenance of those medications’ integrity is dependent upon a controlled environment. If temperatures or humidity levels vary too greatly, the molecular makeup of the medicines can be altered. Cannabis is no different than other plant-derived medicines; its potency and its effect upon consumption can be diminished if the buds are processed in an uncontrolled facility.

Manufacturing pre-rolls in a climate controlled environment is particularly important because the product requires ground flower. Grinding up buds can cause the loss of trichomes and terpenes, especially in a facility without controlled conditions. Even the highest quality pre-roll machines become less effective when temperatures and humidity levels are not maintained in the production facility.

While many companies producing pre-roll machines provide installation services, the most reputable retailers include climate control advice to their customers. If a company is eager to sell their equipment without discussing the importance of a controlled environment, they may not be well-prepared to help manufacturers integrate a new piece of technology into their operations. When it comes to the ongoing successful operation of pre-roll machines, a controlled environment is key.

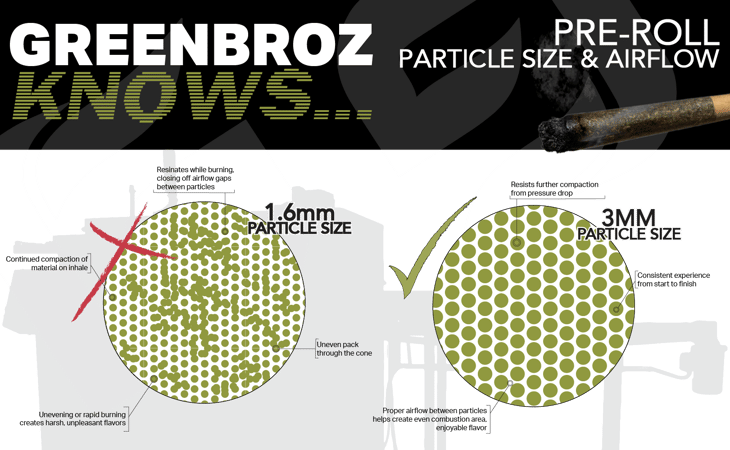

Many cannabis connoisseurs prefer to break up their flower by hand instead of using a manual grinder or shredder. When packing a cone or rolling a joint, the size of the grind influences the way the air flows through the flower when it is smoked. If the particle size is too fine, it can be difficult to establish sufficient airflow for a positive smoking experience. The same is true for pre-rolls produced on an industrial scale. Manufacturers need the ability to adjust and dial in a variety of grind sizes to pack different types of pre-rolls. There are already a wide range of pre-roll varieties on the market, and the diversity of the pre-roll market will only continue to expand.

A larger grind size helps optimize air flow in a pre-roll, but not all automated pre-roll machines are designed to accommodate those larger sizes. The way some machines are designed makes them more susceptible to clogging when packing with a particle size any larger than 2 millimeters. After testing the air flow in different joints, GreenBroz found that 3-millimeter particles burn the most evenly and give consumers a smoother smoking experience, and the Holy Roller can accommodate whatever size grind the operator chooses to use.

Because we have an assortment of pre-rolls on the market, manufacturers need machines that can produce pre-rolls in various sizes. Today’s best pre-roll machines can adapt to produce different sized pre-rolls. While some machines are built to fit different sized cones, machines like the GreenBroz Holy Roller can make any size joint out of a single cone. The Holy Roller can fill joints from 0.3 grams to full grams with the same cone. With just one paper size, manufacturers can fulfill multiple product SKUs, simplifying orders, storage, and inventory maintenance.

Because pre-roll packs and smaller dogwalker joints are so popular among consumers, cannabis companies are eager to produce their own line of smaller pre-rolls. However, small pre-rolls are more susceptible to flaws because there is less flower for air to flow through when the joint is smoked. If a half-gram pre-roll canoes or burns unevenly, the entire joint becomes useless to the consumer. Investing in a pre-roll machine that adapts to different pre-roll sizes is important for many cannabis companies, but those who invest in a pre-roll machine with features that ensure precision will impress consumers and inspire repeat purchases.

Ensuring the precise weight of each pre-roll is important for both compliance and profitability. If a cannabis brand is selling pre-rolls containing more flower than advertised, they could face significant fines and consequences from state regulators. Manufacturers are also going to experience costly product loss if their pre-roll machine is overfilling cones. Machines with extensive weighing features can help manufacturers ensure they produce accurate pre-rolls on an industrial scale using any strain.

Because fully automated pre-roll machines are still fairly new to the industry, designs vary greatly. Some pre-roll machines weigh their cones before and after they are packed, some have software features that track the density of the pre-roll as it's packed, and some require operators to manually weigh their pre-rolls after the machine packs them. Different machines also have different accuracy percentages, which customers can use to compare the efficacy of their pre-roll machines.

The Green Broz Holy Roller uses unique active weighing technology. The machine begins by weighing the pre-roll cone itself, then it actively weighs the cone as it is placed in the socket and filled with flower. Before the pre-roll is tamped or twisted, it enters a “fine fill” station, where it is weighed for accuracy within .001 of a gram.

.jpg?width=730&name=IMG_2060%20(1).jpg)

The weight and density of the pre-roll are essential to a consistent consumer experience, but without a precise and high-quality finish, the product's integrity is compromised. Whether a pre-

roll is twisted or tamped, the precision with which the machine can finish the joint will affect the quality of the customer’s smoking experience. If a paper is twisted unsymmetrically after packing, it doesn’t matter if the joint is packed evenly because it will not light from the center. The air flow will be uneven, and the pre-roll will likely burn more quickly on one side to the disappointment of the consumer.

In an industry where regulations are still evolving, cannabis companies must take a lot of quality assurance measures independently. There are numerous pre-roll machines on the market with the ability to both twist and tamp, but the consistency and accuracy with which this action is carried out is paramount to producing a reputable product. Companies with engineers who work on both the development of the equipment and its integration in the industry can demonstrate the integrity of their machinery. When companies are willing to demonstrate the quality of their product, they are more likely to have thoroughly tested their own equipment.

Never miss a blog posting or exclusive shop deal!

In the world of cannabis cultivation, your equipment is your best friend. Keeping it in pristine condition isn't just about prolonging its lifespan;...

In Humboldt County's green expanses, Jonah Carrington is changing the cannabis game with the GreenBroz Model G Precision Grinder. From his Santa...

Cannabis has come a long way, from black market only to decriminalization, and being legalized in one form or another is just about every state. The...